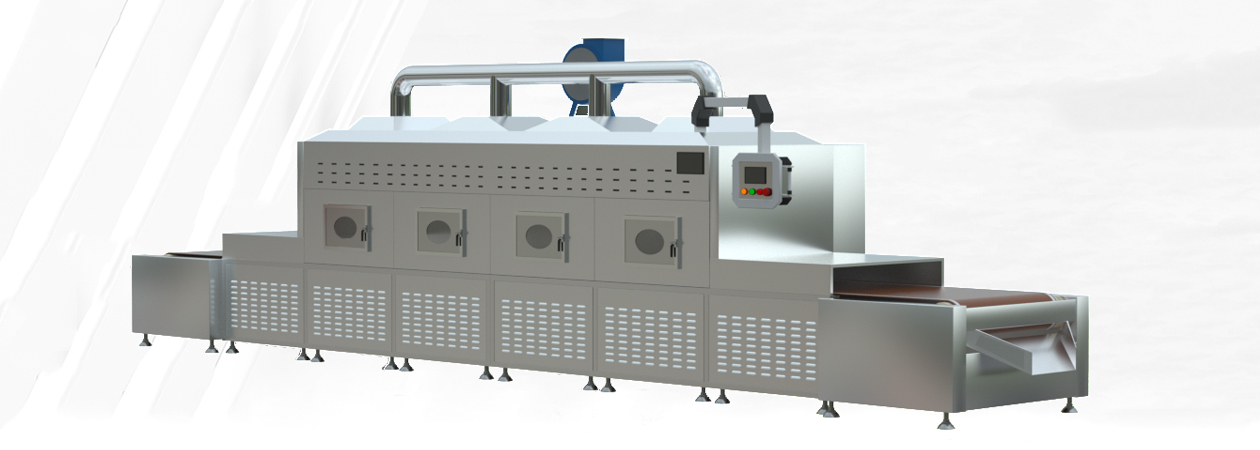

Microwave drying and sterilization machine for chilli and chilli chips

Microwave drying and sterilization machine for chilli and chilli chips:

The microwave drying and sterilization equipment for chilli and chilli chips is a special drying and sterilization machine developed by our company for chilli products. It has been adopted by many Korean enterprises and domestic well-known enterprises and has won praise from customers. Its features: high efficiency and energy saving, good sterilization effect, (reaching the export standard) simple operation, safety and health.

The microwave drying and sterilization machine for chilli and chilli chips is applicable to the drying, dehydration, sterilization, preservation, mold prevention and sterilization of pepper powder, chilli powder, carrageenan powder, soybean powder, sesame powder, nutritional Bao health products, snack food, agricultural and sideline products, various meat small packages, fish fillets, fish cells, etc Heating, drying and sterilization of condiments (chicken essence, beef essence, pork essence, yeast essence, seafood essence, seafood soup essence, seafood soup powder, spareribs essence, spareribs soup essence, spareribs soup powder, spices, pepper powder) by expanded microwave equipment. It is also suitable for drying dehydrated vegetables, seafood spices (kelp, laver, fish, shrimp).

Characteristics of microwave drying and sterilization machine for pepper and pepper chips:

1. Microwave energy saving and high efficiency. Microwave directly acts on materials, so there is no additional heat loss. Neither the air in the furnace nor the corresponding containers will generate heat, so the thermal efficiency is very high. The production environment is also significantly improved. Compared with far-infrared heating, it can save 30% electricity.

2. Short microwave time and high efficiency. Microwave heating sterilization is a process that makes the heated object become a heating body without heat conduction. The microwave penetrates the inside and outside of the object from all directions, and makes the object achieve uniform heating and sterilization in a very short time, which greatly shortens the drying and sterilization time, thus improving the output.

3. The microwave machine is easy to control and the technology is advanced. Compared with the conventional method, the equipment is ready for use; No thermal inertia, flexible and convenient operation; The microwave power and transmission speed are adjustable. In microwave heating, drying and sterilization, there is no waste water, waste gas and waste residue, which is a safe and harmless high-tech.

4. Good sterilization effect. It has been proved by practice that E. coli can be completely killed at 70 ℃ by microwave sterilization, and the total number of bacteria can be greatly reduced at 80 ~ 90 ℃ in only 5 ~ 10 minutes. The speed is fast and the time is short, so the nutrition and traditional flavor in the food are preserved.

5. Extend shelf life. After microwave sterilization, the shelf life of materials can be extended for half a year, which has a significant effect on improving product quality and prolonging storage cycle

Our company has test prototypes of various types of microwave equipment. New and old customers are welcome to visit and investigate. We can customize microwave equipment of different specifications according to your output and plant area, and provide you with one-stop technical services.

The microwave drying and sterilization equipment for chilli and chilli chips is a special drying and sterilization machine developed by our company for chilli products. It has been adopted by many Korean enterprises and domestic well-known enterprises and has won praise from customers. Its features: high efficiency and energy saving, good sterilization effect, (reaching the export standard) simple operation, safety and health.

The microwave drying and sterilization machine for chilli and chilli chips is applicable to the drying, dehydration, sterilization, preservation, mold prevention and sterilization of pepper powder, chilli powder, carrageenan powder, soybean powder, sesame powder, nutritional Bao health products, snack food, agricultural and sideline products, various meat small packages, fish fillets, fish cells, etc Heating, drying and sterilization of condiments (chicken essence, beef essence, pork essence, yeast essence, seafood essence, seafood soup essence, seafood soup powder, spareribs essence, spareribs soup essence, spareribs soup powder, spices, pepper powder) by expanded microwave equipment. It is also suitable for drying dehydrated vegetables, seafood spices (kelp, laver, fish, shrimp).

Characteristics of microwave drying and sterilization machine for pepper and pepper chips:

1. Microwave energy saving and high efficiency. Microwave directly acts on materials, so there is no additional heat loss. Neither the air in the furnace nor the corresponding containers will generate heat, so the thermal efficiency is very high. The production environment is also significantly improved. Compared with far-infrared heating, it can save 30% electricity.

2. Short microwave time and high efficiency. Microwave heating sterilization is a process that makes the heated object become a heating body without heat conduction. The microwave penetrates the inside and outside of the object from all directions, and makes the object achieve uniform heating and sterilization in a very short time, which greatly shortens the drying and sterilization time, thus improving the output.

3. The microwave machine is easy to control and the technology is advanced. Compared with the conventional method, the equipment is ready for use; No thermal inertia, flexible and convenient operation; The microwave power and transmission speed are adjustable. In microwave heating, drying and sterilization, there is no waste water, waste gas and waste residue, which is a safe and harmless high-tech.

4. Good sterilization effect. It has been proved by practice that E. coli can be completely killed at 70 ℃ by microwave sterilization, and the total number of bacteria can be greatly reduced at 80 ~ 90 ℃ in only 5 ~ 10 minutes. The speed is fast and the time is short, so the nutrition and traditional flavor in the food are preserved.

5. Extend shelf life. After microwave sterilization, the shelf life of materials can be extended for half a year, which has a significant effect on improving product quality and prolonging storage cycle

Our company has test prototypes of various types of microwave equipment. New and old customers are welcome to visit and investigate. We can customize microwave equipment of different specifications according to your output and plant area, and provide you with one-stop technical services.

- up:Paper tube and paper holder microwave drying machine

- next:It's the last one

It is committed to upgrading the overall technical level of microwave drying equipment, single extruder and extruder production line

With advanced technology, strict management and perfect service, the company has been highly praised by users at home and abroad, and has achieved very impressive performance, occupying a place in the expansion industry

-

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305 -

E-Mail:

E-Mail:

info@dongxuya.com -

Company ADD:

Company ADD:

No.14,DM Industrial Park,Jinan City,China

Scan

Copyright ©2022 SHANDONG DONGXUYA MACHINERY CO., LTD Record No:魯ICP#16042769-2 Technical Support:51La