Flower Drying And Fixing Machine

Characteristics of flower drying and fixing machine:

1. Rapid drying

Microwave drying is totally different from traditional drying. It is a process that makes the dried material itself become a heating body without heat conduction. Therefore, although the material has poor thermal conductivity, it can reach the drying temperature in a very short time.

2、Dry evenly

No matter what the shape of each part of the object is, microwave drying can make the surface and interior of the object evenly permeate electromagnetic waves at the same time to generate heat energy. Therefore, the drying uniformity is good, and there will be no external coke endogenous phenomenon.

3、Energy saving and high efficiency

Because the material containing water is easy to absorb microwave and generate heat, there is almost no other loss except a small amount of transmission loss. Therefore, it has high thermal efficiency and energy saving. It saves more than 1/3 energy than infrared drying.

4. Mould proof, sterilization and preservation

Microwave drying has thermal and biological effects, and can sterilize and prevent mold at lower temperature. As the drying speed is fast and the time is short, the activity of the material, the vitamins in the food, the original color and nutrients can be preserved to the greatest extent.

5. Advanced technology

Immediate drying and termination can be achieved by controlling the microwave power. The application of man-machine interface and PLC can be used for programmable automatic control of drying process and drying process specification.

6. Safe and harmless

Since the microwave energy is controlled to work in the drying room and waveguide made of metal, there is little microwave leakage, no radiation hazard and harmful gas emission, no waste heat and dust pollution, neither food nor environment pollution.

- up:Lotus Leaf Drying And Fixing Machine

- next:It's the last one

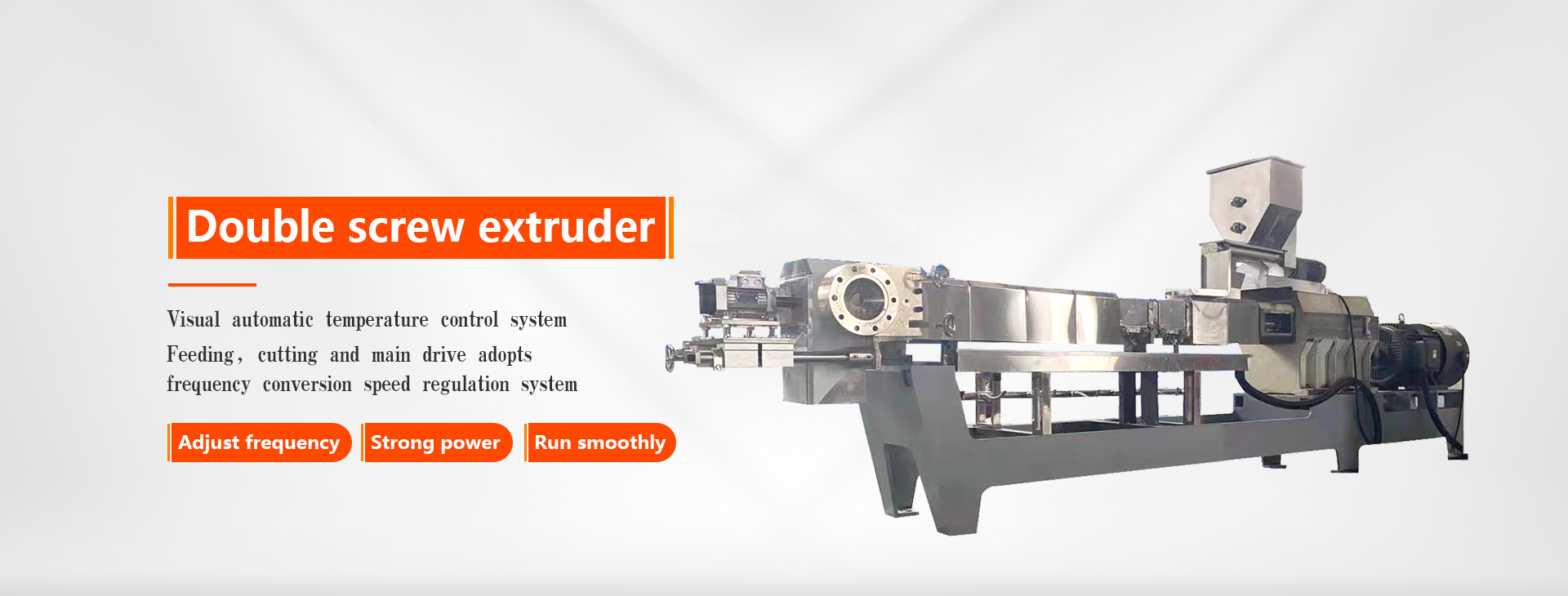

It is committed to upgrading the overall technical level of microwave drying equipment, single extruder and extruder production line

With advanced technology, strict management and perfect service, the company has been highly praised by users at home and abroad, and has achieved very impressive performance, occupying a place in the expansion industry

-

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305 -

E-Mail:

E-Mail:

info@dongxuya.com -

Company ADD:

Company ADD:

No.14,DM Industrial Park,Jinan City,China

Scan

Copyright ©2022 SHANDONG DONGXUYA MACHINERY CO., LTD Record No:魯ICP#16042769-2 Technical Support:51La