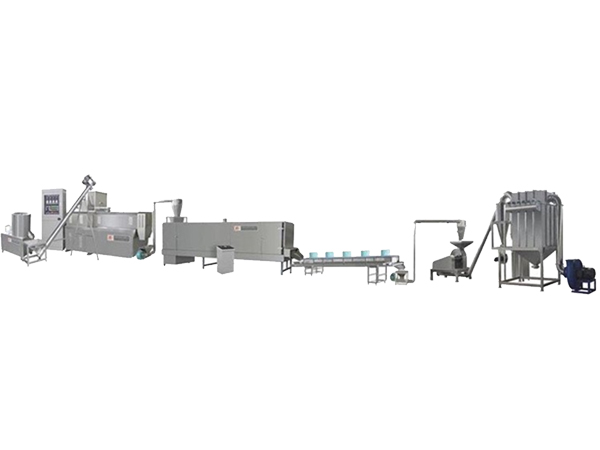

Modified starch and pregelatinized starch production line

Brief introduction of industrial coating, modified starch production line and pregelatinized starch production line:

The original physical or chemical properties of raw starch will be changed in varying degrees after being treated by some method. Modified starch is a kind of modified starch. In order to improve the properties of starch and expand its application range, physical, chemical or enzymatic treatment is used to introduce new functional groups into starch molecules or change the size of starch molecules and the properties of starch particles, so as to change the natural characteristics of starch (such as gelatinization temperature, thermal viscosity and its stability, freeze-thaw stability, gel force, film-forming property, transparency, etc.), making it more suitable for certain application requirements. This kind of starch that changes its properties after secondary processing is collectively referred to as modified starch.

The first purpose of denaturation is to meet the requirements of various industrial applications. For example, high temperature technology (can sterilization) requires good high-temperature viscosity stability of starch, frozen food requires good freeze-thaw stability of starch, and jelly food requires good transparency and film-forming property. The second is to open up new uses of starch and expand the scope of application. For example, starch is used in textile; Hydroxyethyl starch and hydroxypropyl starch replace plasma; High cross-linked starch replaces talc powder for surgical gloves.

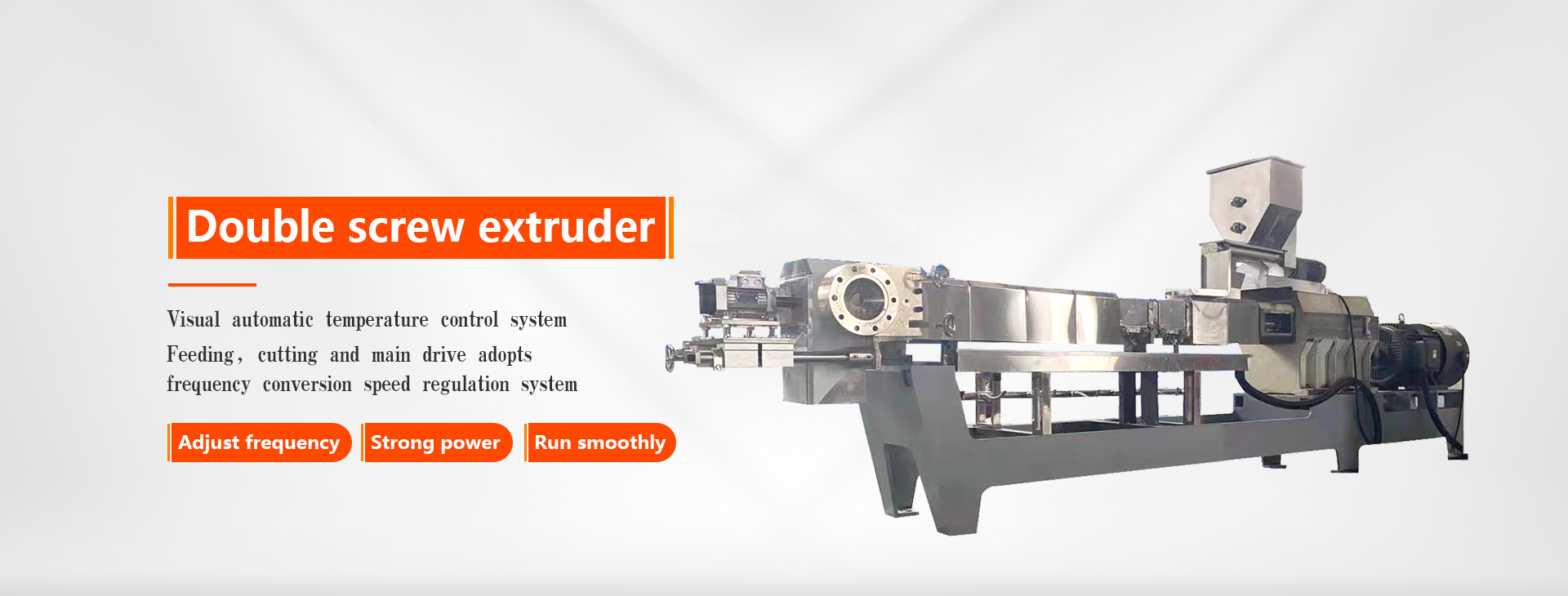

The equipment produced by our company has been professionally designed to adjust the machine cavity and screw structure, so that the functions of modified starch have been diversified. The modified starch series products produced are suitable for textile, food, paper making, building materials, casting, oil drilling and other fields. With the deepening of research, extruders will play an increasingly important role in the modified starch Market. The machine is composed of feeding system, extrusion system, rotary cutting system, heating system, transmission system and cooling system.

Technological process:

Raw material preparation - mixing - conveying - extrusion - conveying - drying - cooling - conveying - crushing - packaging

Configuration:

1. Mixer:Starch (corn starch, cassava starch, potato starch, etc.) is added with a certain amount of water alone or mixed with some additives, and is fully stirred.

2. Screw conveyor:The motor is used to drive the screw conveying, and the mixed raw materials are transported to the feeding bucket of the extruder to ensure convenient and fast feeding.

3. Extruder:There is a special control cabinet, which can extrude modified starch particles under high temperature and high pressure. Different products can be produced by adjusting the process and changing the mold.

4. Hoist:Transport the particles to the oven, and the height of the elevator is determined according to the oven.

5. Oven:The oven is an electric oven, and the temperature is between 0-200 ℃ and can be adjusted by the control cabinet.

6. Pulverizer:According to the requirements of modified starch, different pulverizers are selected for crushing.

Our company is constantly upgrading according to market tastes. Production equipment has also been constantly updated to meet the production needs of new markets. The expanded food production line has a good reputation in the industry, which is inseparable from advanced production technology. Our company provides a full range of services from production technology to product packaging. Reduce some worries of production for customers.

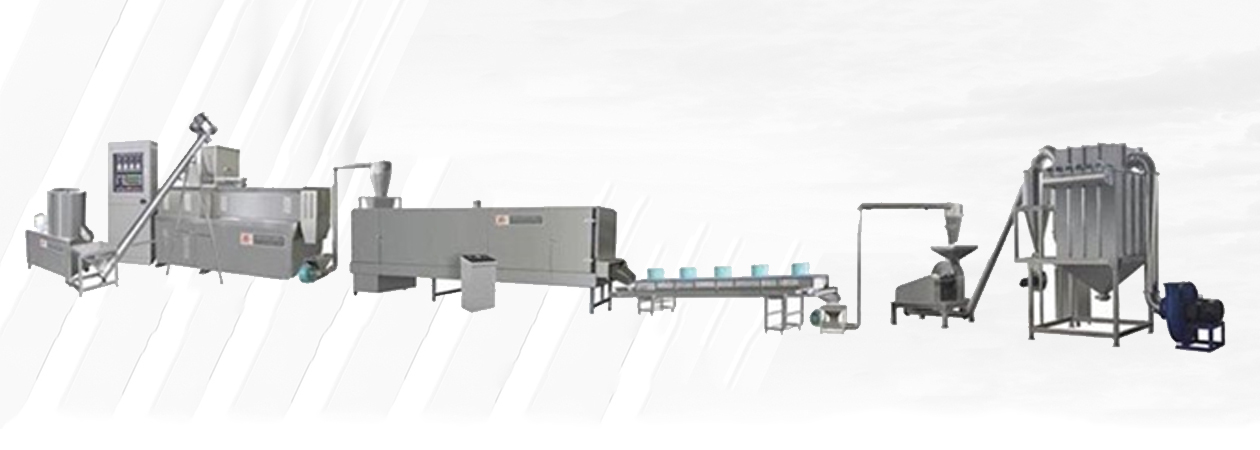

The original physical or chemical properties of raw starch will be changed in varying degrees after being treated by some method. Modified starch is a kind of modified starch. In order to improve the properties of starch and expand its application range, physical, chemical or enzymatic treatment is used to introduce new functional groups into starch molecules or change the size of starch molecules and the properties of starch particles, so as to change the natural characteristics of starch (such as gelatinization temperature, thermal viscosity and its stability, freeze-thaw stability, gel force, film-forming property, transparency, etc.), making it more suitable for certain application requirements. This kind of starch that changes its properties after secondary processing is collectively referred to as modified starch.

The first purpose of denaturation is to meet the requirements of various industrial applications. For example, high temperature technology (can sterilization) requires good high-temperature viscosity stability of starch, frozen food requires good freeze-thaw stability of starch, and jelly food requires good transparency and film-forming property. The second is to open up new uses of starch and expand the scope of application. For example, starch is used in textile; Hydroxyethyl starch and hydroxypropyl starch replace plasma; High cross-linked starch replaces talc powder for surgical gloves.

The equipment produced by our company has been professionally designed to adjust the machine cavity and screw structure, so that the functions of modified starch have been diversified. The modified starch series products produced are suitable for textile, food, paper making, building materials, casting, oil drilling and other fields. With the deepening of research, extruders will play an increasingly important role in the modified starch Market. The machine is composed of feeding system, extrusion system, rotary cutting system, heating system, transmission system and cooling system.

Technological process:

Raw material preparation - mixing - conveying - extrusion - conveying - drying - cooling - conveying - crushing - packaging

Configuration:

1. Mixer:Starch (corn starch, cassava starch, potato starch, etc.) is added with a certain amount of water alone or mixed with some additives, and is fully stirred.

2. Screw conveyor:The motor is used to drive the screw conveying, and the mixed raw materials are transported to the feeding bucket of the extruder to ensure convenient and fast feeding.

3. Extruder:There is a special control cabinet, which can extrude modified starch particles under high temperature and high pressure. Different products can be produced by adjusting the process and changing the mold.

4. Hoist:Transport the particles to the oven, and the height of the elevator is determined according to the oven.

5. Oven:The oven is an electric oven, and the temperature is between 0-200 ℃ and can be adjusted by the control cabinet.

6. Pulverizer:According to the requirements of modified starch, different pulverizers are selected for crushing.

Our company is constantly upgrading according to market tastes. Production equipment has also been constantly updated to meet the production needs of new markets. The expanded food production line has a good reputation in the industry, which is inseparable from advanced production technology. Our company provides a full range of services from production technology to product packaging. Reduce some worries of production for customers.

Sample display of modified starch and pregelatinized starch production line

Product parameters

| Model | Main power |

Installed power |

Actual power |

Capacity |

Size |

|

DXY65-II |

22KW |

70KW |

45KW |

100-150kg/h |

2.5*0.8*1.7m |

|

DXY70-II |

45KW |

100KW |

70KW |

180-240kg/h |

2.5*1.0*1.8m |

|

DXY85-II |

90KW |

170KW |

100KW |

300-400kg/h |

4.3*1.5*1.8m |

Production line display Details display

Modified starch / pregelatinized starch line

- High automatic

- Low cost

- Reduce space

- Stir well

- Good stability

- High output

- up:It's already the first one

- next:It's the last one

It is committed to upgrading the overall technical level of microwave drying equipment, single extruder and extruder production line

With advanced technology, strict management and perfect service, the company has been highly praised by users at home and abroad, and has achieved very impressive performance, occupying a place in the expansion industry

-

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305 -

E-Mail:

E-Mail:

info@dongxuya.com -

Company ADD:

Company ADD:

No.14,DM Industrial Park,Jinan City,China

Scan

Copyright ©2022 SHANDONG DONGXUYA MACHINERY CO., LTD Record No:魯ICP#16042769-2 Technical Support:51La