Core Filling Snack Production Line

Core Filling Snack Production Line:

Core Filling Snack Production Line is a new generation production line developed by Shandong dongxuya Machinery Co., Ltd. It has a high degree of automation from raw material preparation, extrusion and expansion, sandwich, molding, cutting, spraying, seasoning to finished products at one time. The production line has the characteristics of many models, flexible configuration, wide range of raw materials, many types of products, simple operation and so on. The configuration of the production line can produce Taiwan, China rice cakes, sandwich tubes, sandwich rice fruits, wheat burning, wheat flavored chicken flavor pieces, nutritional breakfast, cornflakes and other products. The puffed food has crispy taste, easy digestion, unique flavor and easy to carry. It is an ideal snack food for consumers

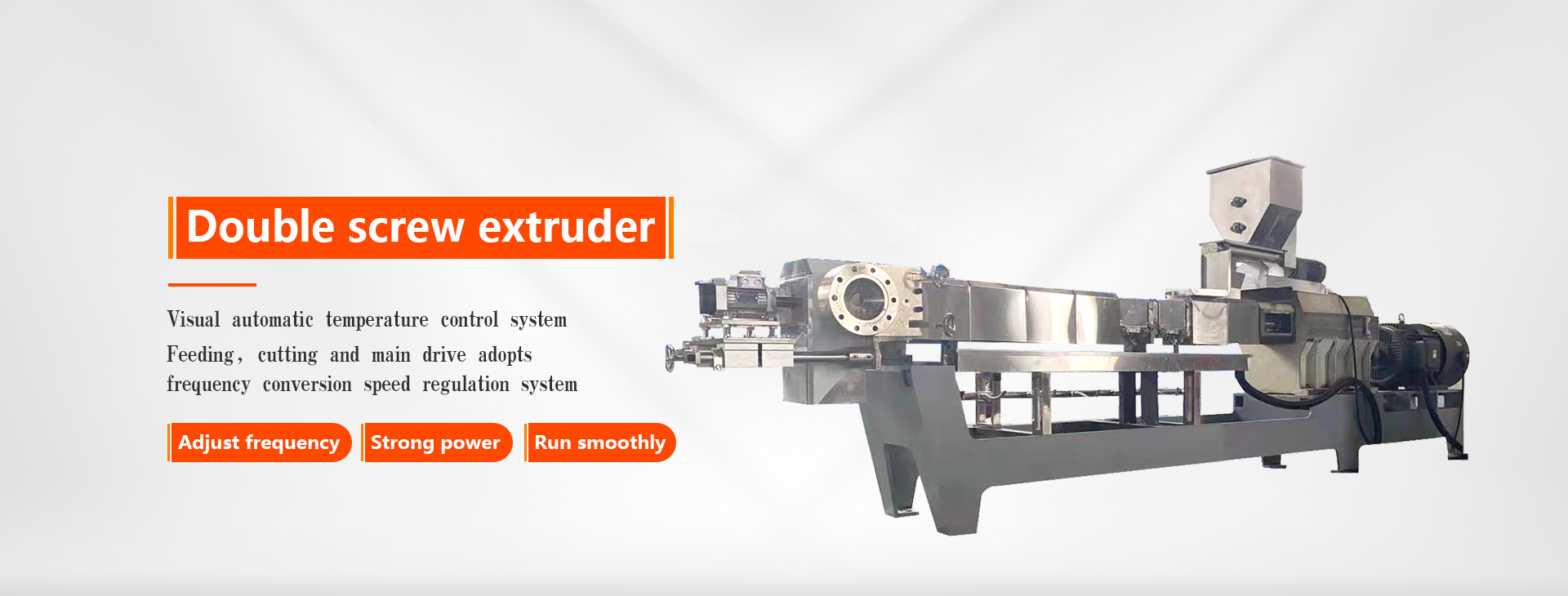

Technological Process::

Mixing-Extruder-core filling-Shaper-dryer-Oil spray seasoning-cooling-packing

Process composition:

1、Mixer:According to the output of the production line, different types of powder mixers are selected. There are three main types for you to choose: 25kg and 50kg 100kg.

2、Screw conveyor:The motor is used for power screw transmission to ensure convenient and fast feeding。

3、Extruder:According to the output of the production line, different models of expansion host are selected, and the output can range from 130kg/h to 1500kg / h. corn flour, rice flour, flour, corn starch and other raw materials can be used. The mold can be changed for the specific product shape.

4、Hoister:Feed is conveyed to the oven, and the height of the elevator is determined according to the oven, or the air blower can be selected.

5、Multilayer oven:Most of the ovens are electric ovens, and the temperature between 0-200 degrees can be adjusted by the control cabinet. The interior is a stainless steel double-layer mesh belt, and the baking time can be adjusted according to the speed. There are three-layer, five layer and seven layer stainless steel ovens;

6、Seasoning line:There are octagonal cylinder, lifting single drum and double drum seasoning lines, which are configured according to the output and product nature.

7、Cooling delivery:Filter the excess external materials and grease on the surface of materials to ensure product quality and save the use of external materials.

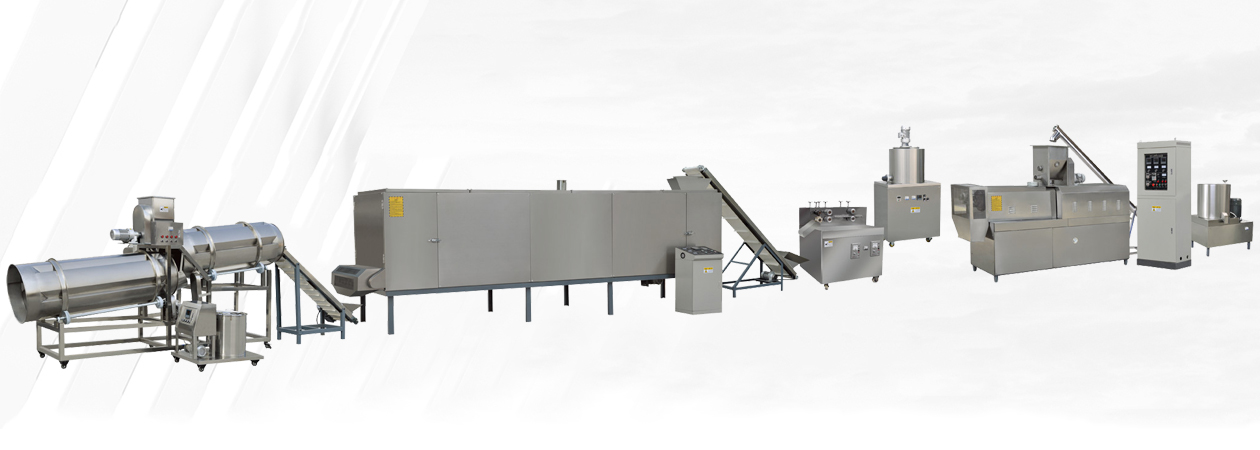

Machine configuration:

Mixer→Screw conveyor→Twin-screw extruder→Core filler-Shaping and cutting machine→Hoister→Dryer→Double drum seasoning line

Sample display

Technical Parameter

| Model | Installed power | Power consumption | Capacity | Overall dimension |

| DXY65-Ⅲ | 74KW | 52KW | 100-150kg/h | 17000*1300*2200mm |

| DXY70 | 105KW | 75KW | 200-260kg/h | 20000*1500*2200mm |

| DXY85 | 205KW | 150KW | 400-500kg/h | 30000*1500*2600mm |

Production line display details display

Core filling snack production line

- Highly automatic

- Low cost

- Reduce space

- Stir well

- Good stability

- High output

- up:Snacks Food /Core Filling Production Line

- next:It's the last one

It is committed to upgrading the overall technical level of microwave drying equipment, single extruder and extruder production line

With advanced technology, strict management and perfect service, the company has been highly praised by users at home and abroad, and has achieved very impressive performance, occupying a place in the expansion industry

-

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305 -

E-Mail:

E-Mail:

info@dongxuya.com -

Company ADD:

Company ADD:

No.14,DM Industrial Park,Jinan City,China

Scan

Copyright ©2022 SHANDONG DONGXUYA MACHINERY CO., LTD Record No:魯ICP#16042769-2 Technical Support:51La