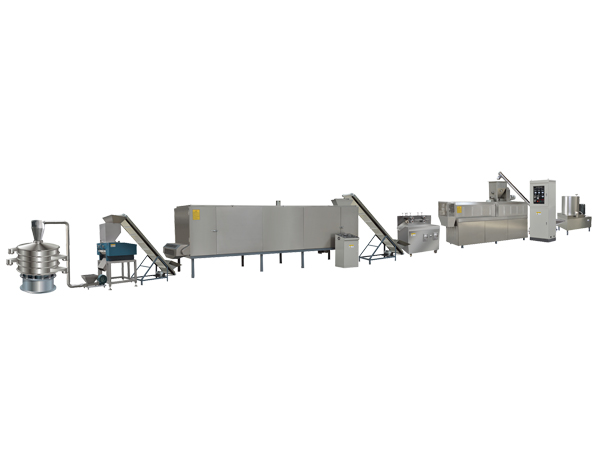

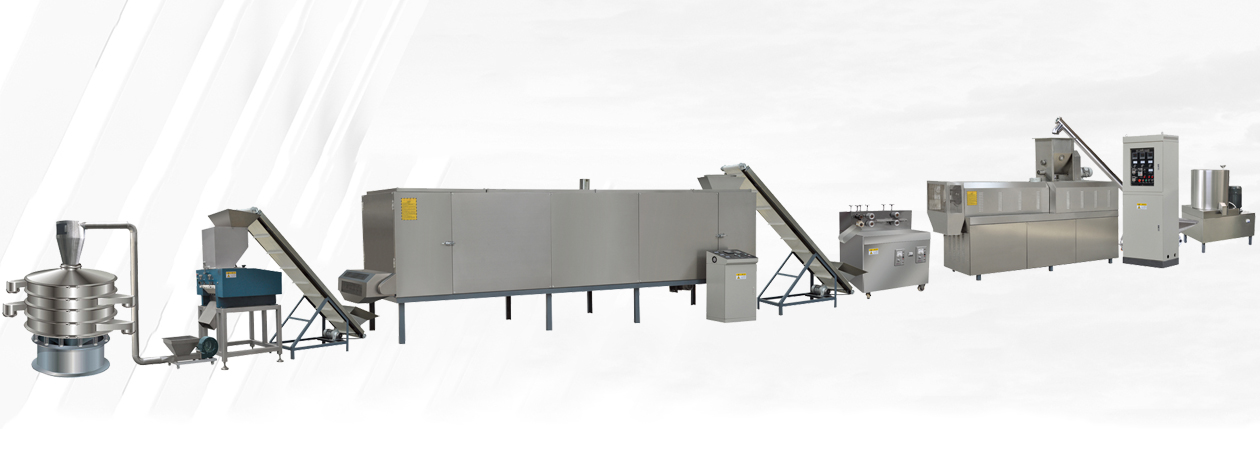

Bread Crumbs Production Line

Bread Crumbs Production Line:

The bread crumbs machine developed by dongxuya machinery uses a twin-screw extruder to produce bread crumbs , which changes the traditional production process of bread crumbs and is another application of twin-screw extrusion technology. Bread crumbs machinery is a full-automatic production line, from raw material mixing, transportation, cooking and ripening, forming, drying and uniform production line; In addition to flour, the available raw materials include rice flour, corn flour, corn starch, soybean flour, etc; It can produce various shapes of bread crumbs, including needle, granule, snowflake, flake, star or various shapes, to meet the different needs of customers. The twin-screw extruder, the main equipment of bread crumbs machinery, can complete many production processes of traditional motor bread crumbs, such as raw material mixing, dough mixing, pelletizing, dough passing (dough pressing machine), fermentation, maturation and so on. It is a hot extrusion process with high temperature, high pressure, short time and low moisture. Compared with the traditional production process, it has fewer production personnel, shorter production process, higher unit output, energy saving and lower production costs; Simple equipment matching, small land occupation and convenient operation; No waste, sewage and waste gas, green and environmental protection; It is easy to use raw materials, change product varieties and shapes, and make products more diverse. Bread crumbs is a kind of food additive used for the surface of fried food. It is used for frying chicken legs, chicken wings, fish chops, seafood (shrimp), Western steak, onion rings, etc. it can make fried food crisp outside and tender inside, crisp and delicious in taste, rich and diverse in taste.

Composition of production line:Mixer→Screw conveyor→Extruder→Multifunctional-Shaper→Large Hoister→Powder crumbs machine→Z-conveyor→Chaff sifter→Five layer oven

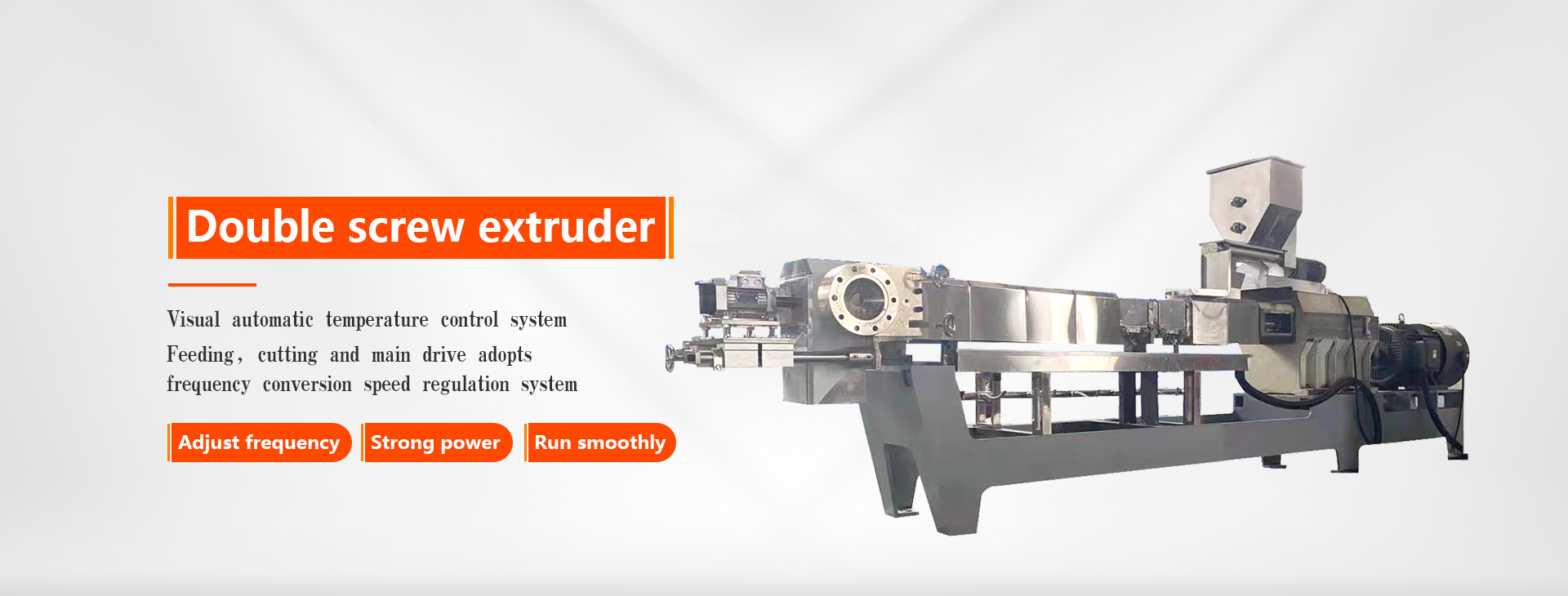

Host characteristics:

1. Touch screen centralized control, accurate and convenient

2. Direct connection drive between motor and distribution box, less energy loss

3. Imported bearing group is adopted, with strong bearing capacity

4. The cylinder is equipped with a water injection device to better meet the requirements of raw materials and quality

5. High speed tool steel screw, hardness HRC ≥ 62, long service life

6. Building block combined screw can be combined randomly according to different raw materials and products

7. Linear bearing tool adjustment, safe, accurate and fast

Technical support for bread bran production line:

1. Consultation on equipment, process, packaging, standardized plant layout, etc. before the project;

2. Consultation and training on equipment operation and process technology during project implementation;

3. Provide system solutions for your production and match your needs;

4. It can be designed and manufactured according to your requirements;

5. It can help you to upgrade the existing product line, eliminate weak links and improve production efficiency;

6. Our workshop integrates experiments, demonstrations and training to provide you with services;

7. Our workshop can test your products and process to select the process equipment suitable for you.

Sample display

Technica Parameter

| Model | Installed Power | Power Consumption | Capacity | Overall Dimension |

| DXY65-Ⅲ | 74KW | 52KW | 100-150kg/h | 17000*1300*2200mm |

| DXY70 | 105KW | 75KW | 200-260kg/h | 20000*1500*2200mm |

| DXY85 | 205KW | 150KW | 400-500kg/h | 30000*1500*2600mm |

Production line display details display

Bread crumb production line

- High automatic

- low cost

- Reduce space

- Stir well

- Good stability

- High output

- up:It's already the first one

- next:It's the last one

It is committed to upgrading the overall technical level of microwave drying equipment, single extruder and extruder production line

With advanced technology, strict management and perfect service, the company has been highly praised by users at home and abroad, and has achieved very impressive performance, occupying a place in the expansion industry

-

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305 -

E-Mail:

E-Mail:

info@dongxuya.com -

Company ADD:

Company ADD:

No.14,DM Industrial Park,Jinan City,China

Scan

Copyright ©2022 SHANDONG DONGXUYA MACHINERY CO., LTD Record No:魯ICP#16042769-2 Technical Support:51La