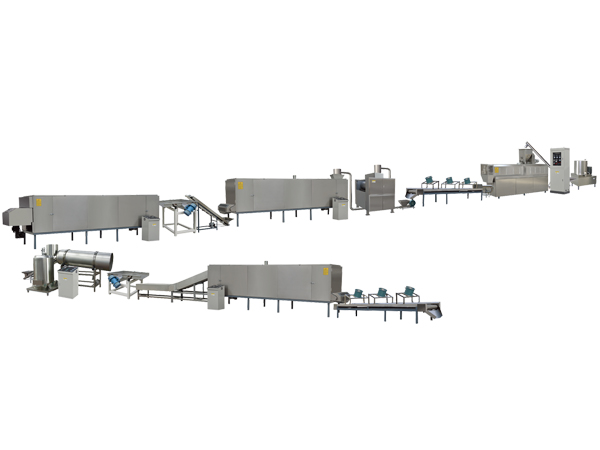

Cornflake and grain circle production line

Breakfast cereal cornflake production line Corn circle production line Puffed food equipment:

reakfast cereal cornflake is a kind of fragile food, which has good rehydration, can't be washed out, has a smooth taste, and has a strong grain flavor. Corn flakes are mainly made from corn flour, mixed with sugar, various vitamins and minerals, and fully kneaded, matured, shaped, pressed, and baked to taste after adding a certain amount of water.

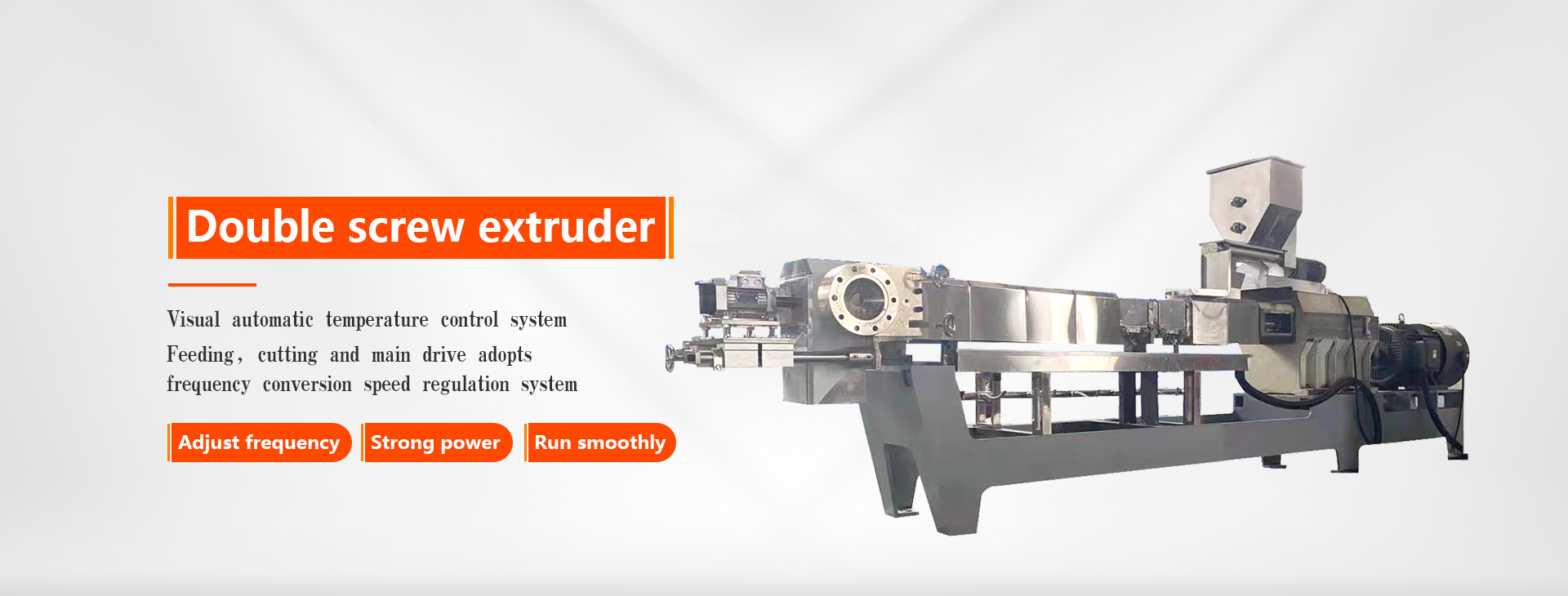

Breakfast cereals, as a convenient, nutritious and balanced food, soon entered thousands of households. In modern processing, extruders are usually used to complete the full kneading, cooking and ripening of the corn flour mixture after adding water, as well as granulation and tablet forming. Cornflakes are rich in nutrients and relatively balanced. They are rare cereal breakfast foods, which are usually eaten together with milk.

Technological process:

Raw material mixing-Extrusion-Cooling-Flaking-First drying-High temperature baking-Sugar spray-Secondary drying-Cooling-Packing

Configuration:

Composition of production line:Mixer→Screw conveyor→Extruder→Vibration sifter→Air conveyor→Flaking machine→Air conveyor→Cooling machine→Five layer oven→Hoist→Vibrating spreader→High temperature dryer→Hoist→Single roller flavoring line→Oven→Cooling conveyor

reakfast cereal cornflake is a kind of fragile food, which has good rehydration, can't be washed out, has a smooth taste, and has a strong grain flavor. Corn flakes are mainly made from corn flour, mixed with sugar, various vitamins and minerals, and fully kneaded, matured, shaped, pressed, and baked to taste after adding a certain amount of water.

Breakfast cereals, as a convenient, nutritious and balanced food, soon entered thousands of households. In modern processing, extruders are usually used to complete the full kneading, cooking and ripening of the corn flour mixture after adding water, as well as granulation and tablet forming. Cornflakes are rich in nutrients and relatively balanced. They are rare cereal breakfast foods, which are usually eaten together with milk.

Technological process:

Raw material mixing-Extrusion-Cooling-Flaking-First drying-High temperature baking-Sugar spray-Secondary drying-Cooling-Packing

Configuration:

Composition of production line:Mixer→Screw conveyor→Extruder→Vibration sifter→Air conveyor→Flaking machine→Air conveyor→Cooling machine→Five layer oven→Hoist→Vibrating spreader→High temperature dryer→Hoist→Single roller flavoring line→Oven→Cooling conveyor

Sample display

Product parameters

| Model | Installed power | Actual power |

Capacity |

Size |

| DXY65-Ⅲ | 130KW | 90KW | 100-150kg/h | 39000*1300*2500mm |

| DXYX70 | 160KW | 120KW | 200-260kg/h | 41000*1500*2500mm |

| DXY85 | 190KW | 140KW | 300-500kg/h | 43000*3500*4300mm |

Production line display Details display

Breakfast cereal/ cornflake production line

- High automatic

- Low cost

- Reduce space

- Stir well

- Good stability

- High output

- up:Cornflake and grain circle production line

- next:It's the last one

It is committed to upgrading the overall technical level of microwave drying equipment, single extruder and extruder production line

With advanced technology, strict management and perfect service, the company has been highly praised by users at home and abroad, and has achieved very impressive performance, occupying a place in the expansion industry

-

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305 -

E-Mail:

E-Mail:

info@dongxuya.com -

Company ADD:

Company ADD:

No.14,DM Industrial Park,Jinan City,China

Scan

Copyright ©2022 SHANDONG DONGXUYA MACHINERY CO., LTD Record No:魯ICP#16042769-2 Technical Support:51La