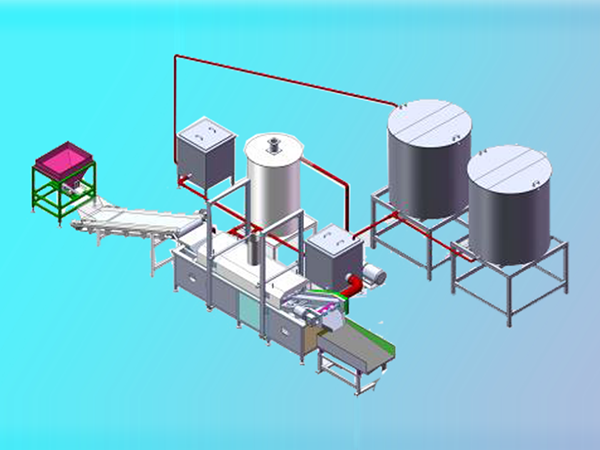

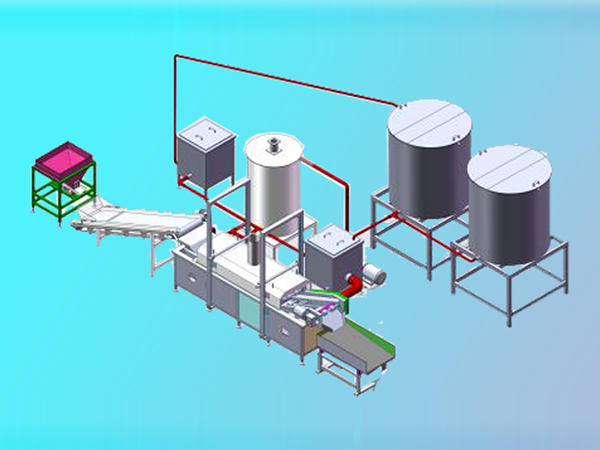

Automatic frying line

Introduction of automatic frying line:

Performance features: the frying mesh belt can be lifted and lowered to facilitate the cleaning of the bottom of the pan. The electric heating is built-in heating to reduce the oil capacity. The inlet of the fryer has a feeding paddle to ensure smooth feeding. The oil circulation direction inside the boiler body follows the feeding direction

Coarse filter: double-layer circulating filtration. The filter residue is kept in the filter box to ensure the frying quality. The overall dimension of the filter box: 1000*1000*1100mm. The strainer is internally installed with an automatic oil makeup valve, which is connected to the oil tank. Three interfaces are reserved, including oil inlet, oil outlet and sewage outlet. The shell of the strainer is provided with insulation function and insulation layer, which improves safety performance and reduces heat consumption

- up:It's already the first one

- next:Semi automatic frying line

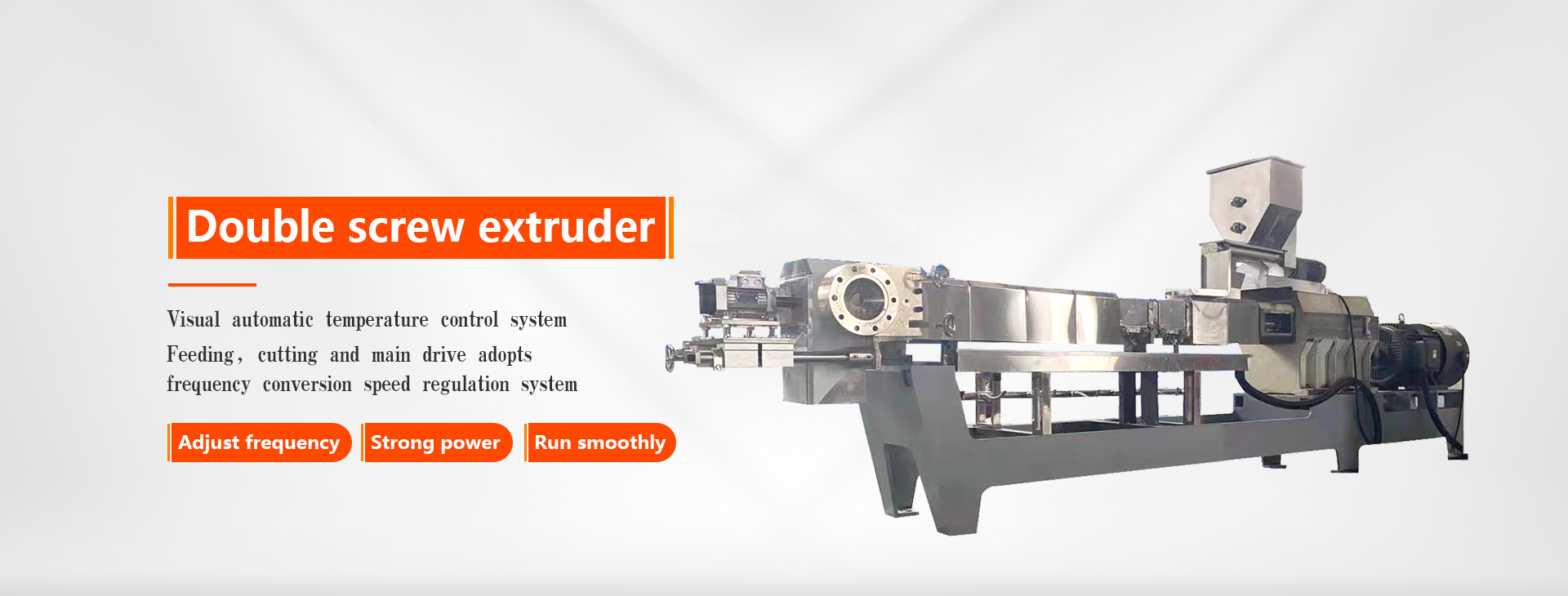

It is committed to upgrading the overall technical level of microwave drying equipment, single extruder and extruder production line

With advanced technology, strict management and perfect service, the company has been highly praised by users at home and abroad, and has achieved very impressive performance, occupying a place in the expansion industry

-

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305 -

E-Mail:

E-Mail:

info@dongxuya.com -

Company ADD:

Company ADD:

No.14,DM Industrial Park,Jinan City,China

Scan