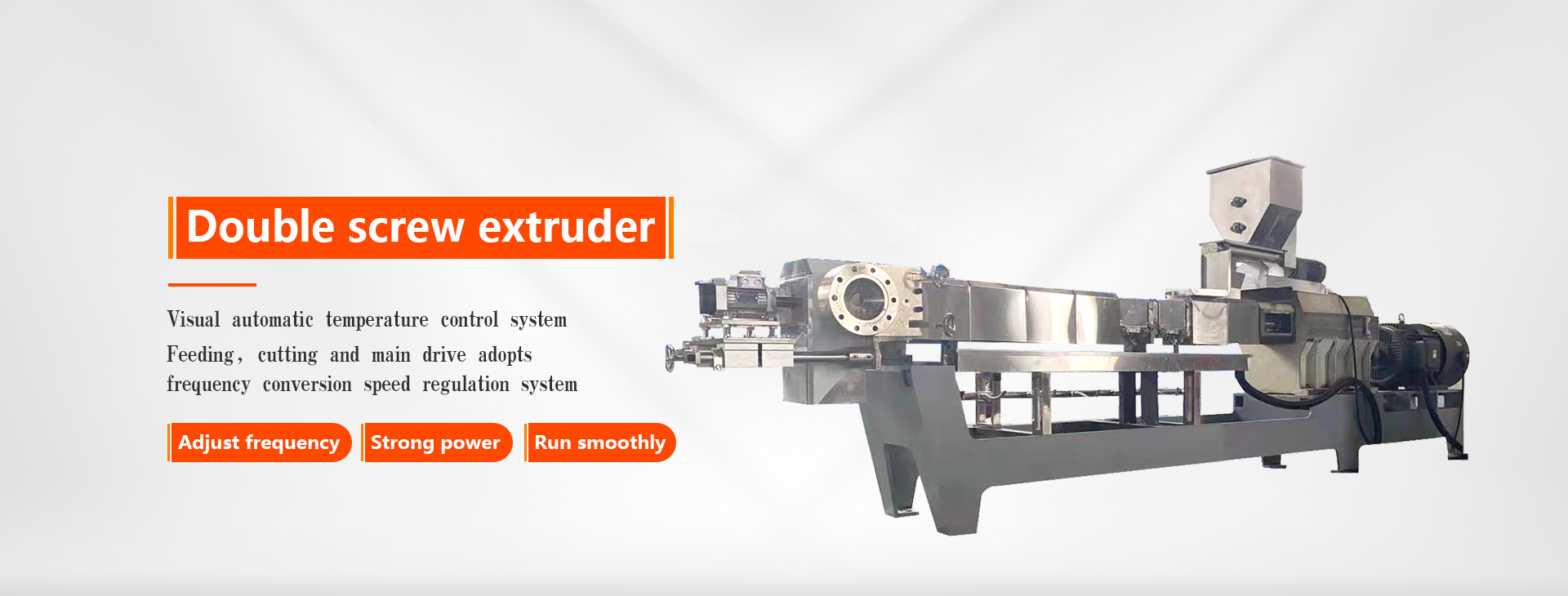

95 Extruder

1. the extruder is composed of control system, feeding system, extrusion system, rotary cutting system, heating system, main drive system, and the rotary cutting, feeding and drive system of the extruder adopts constant torque variable frequency speed regulation, which has strong power, stable operation and energy saving;

2. the extruder screw is made of alloy material by special process, with long service life; It is suitable for a wide range of raw materials and a variety of products.

3. the forced lubrication system extends the service life of the equipment and reduces the mechanical energy consumption;

4. the feeding system adopts single and spiral feeding, and the feeding is uniform and stable;

5. the rotary cutting tool is designed with linear bearing, which can be adjusted accurately.

6. the gearbox cooling system is composed of high-pressure oil pump, filter pump and sub cooling circulating cooler. The center distance of the screw is 67.8mm, the diameter of the screw is 95mm, the length is 1960mm, and the length diameter ratio is 1:18.5.

7. power configuration: main motor 90kw, heating system 30kW, feeding system 2.2kW, rotary cutting 3KW, oil pump 0.55kw.

| Installed power | Main motor power |

Capacity |

Size |

|

95kw |

78kw |

800-1200kg/h |

4.7×1.2×2.5m |

- up:Twin screw extruder

- next:Packing machine

It is committed to upgrading the overall technical level of microwave drying equipment, single extruder and extruder production line

With advanced technology, strict management and perfect service, the company has been highly praised by users at home and abroad, and has achieved very impressive performance, occupying a place in the expansion industry

-

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305 -

E-Mail:

E-Mail:

info@dongxuya.com -

Company ADD:

Company ADD:

No.14,DM Industrial Park,Jinan City,China

Scan