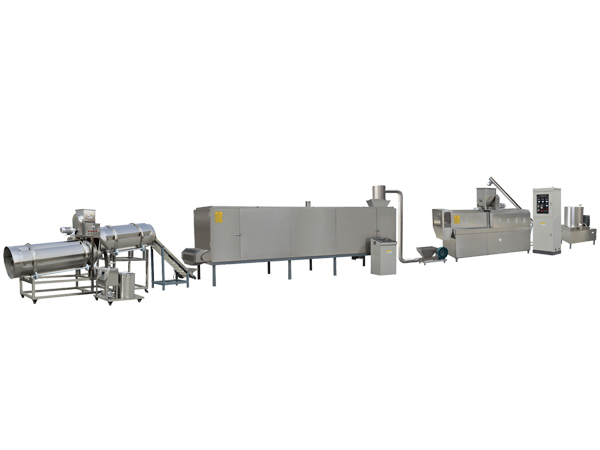

Expanded food production line

Expanded food production line:

The puffed food production line can produce such products as rice dumplings, French fries, potato chips, crispy corners, pizza rolls, etc. Products of various shapes can be produced by changing the abrasives of the extruder and the forming cutter. The more complex three-dimensional products such as miaojiao, Xiaoyu, etc. need to be matched with the plastic cutting equipment. Products of different shapes can be processed by changing the properties of the hob. There are two series of cutting machines, i.e. Guoba potato strip cutting machine, miaojiao and Xiaoyu crisp cutting machine. According to the energy used, the fryers can be divided into two specifications: electric heating type and gas type, According to the structure, it can be divided into round pot batch fryer and tunnel continuous fryer, which are reasonably configured according to the production line capacity and products; The round fryer is mainly composed of a fryer, an oil slitter and a conveyor; The continuous fryer consists of a fryer, a coarse filter, a fine filter, an external heater, a circulating oil pump, an oil storage tank, and a vibration or double head deoiling equipment

technological process:

Raw material mixing - expansion - shaping and cutting - frying - oil spray seasoning - cooling - packaging

Equipment configuration:

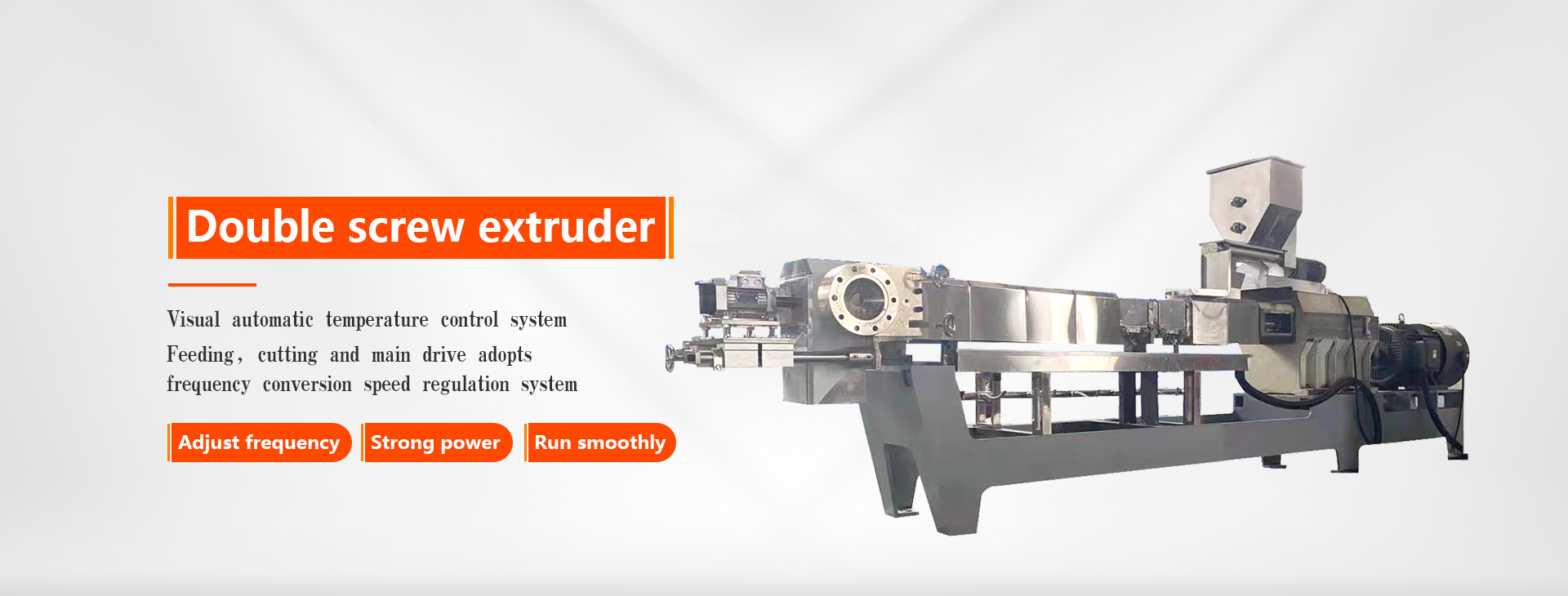

Powder mixer → screw feeding machine → twin screw extruder → shaping and cutting machine → conveyor → elevator - weighing bucket - batch take-off and landing type frying and deoiling machine - elevator - weighing bucket - double barrel rotating octagon flavoring machine

The puffed food production line can produce such products as rice dumplings, French fries, potato chips, crispy corners, pizza rolls, etc. Products of various shapes can be produced by changing the abrasives of the extruder and the forming cutter. The more complex three-dimensional products such as miaojiao, Xiaoyu, etc. need to be matched with the plastic cutting equipment. Products of different shapes can be processed by changing the properties of the hob. There are two series of cutting machines, i.e. Guoba potato strip cutting machine, miaojiao and Xiaoyu crisp cutting machine. According to the energy used, the fryers can be divided into two specifications: electric heating type and gas type, According to the structure, it can be divided into round pot batch fryer and tunnel continuous fryer, which are reasonably configured according to the production line capacity and products; The round fryer is mainly composed of a fryer, an oil slitter and a conveyor; The continuous fryer consists of a fryer, a coarse filter, a fine filter, an external heater, a circulating oil pump, an oil storage tank, and a vibration or double head deoiling equipment

technological process:

Raw material mixing - expansion - shaping and cutting - frying - oil spray seasoning - cooling - packaging

Equipment configuration:

Powder mixer → screw feeding machine → twin screw extruder → shaping and cutting machine → conveyor → elevator - weighing bucket - batch take-off and landing type frying and deoiling machine - elevator - weighing bucket - double barrel rotating octagon flavoring machine

Sample display of expanded food production line

Product parameter

| Extruder | Installed power | Actual power |

Output |

Size |

| DXY65-Ⅲ | 74KW | 52KW | 100-150kg/h | 17000*1300*2200mm |

| DXY70 | 105KW | 75KW | 200-260kg/h | 20000*1500*2200mm |

| DXY85 | 205KW | 150KW | 400-500kg/h | 30000*1500*2600mm |

Production line display Equipment details display

Expanded food production line

- Highly automatic

- Low cost

- Reduce space

- Stir well

- Good stablilty

- High output

It is committed to upgrading the overall technical level of microwave drying equipment, single extruder and extruder production line

With advanced technology, strict management and perfect service, the company has been highly praised by users at home and abroad, and has achieved very impressive performance, occupying a place in the expansion industry

-

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305 -

E-Mail:

E-Mail:

info@dongxuya.com -

Company ADD:

Company ADD:

No.14,DM Industrial Park,Jinan City,China

Scan

Copyright ©2022 SHANDONG DONGXUYA MACHINERY CO., LTD Record No:魯ICP#16042769-2 Technical Support:51La