- Company News

- Industry News

- Question

Industry News

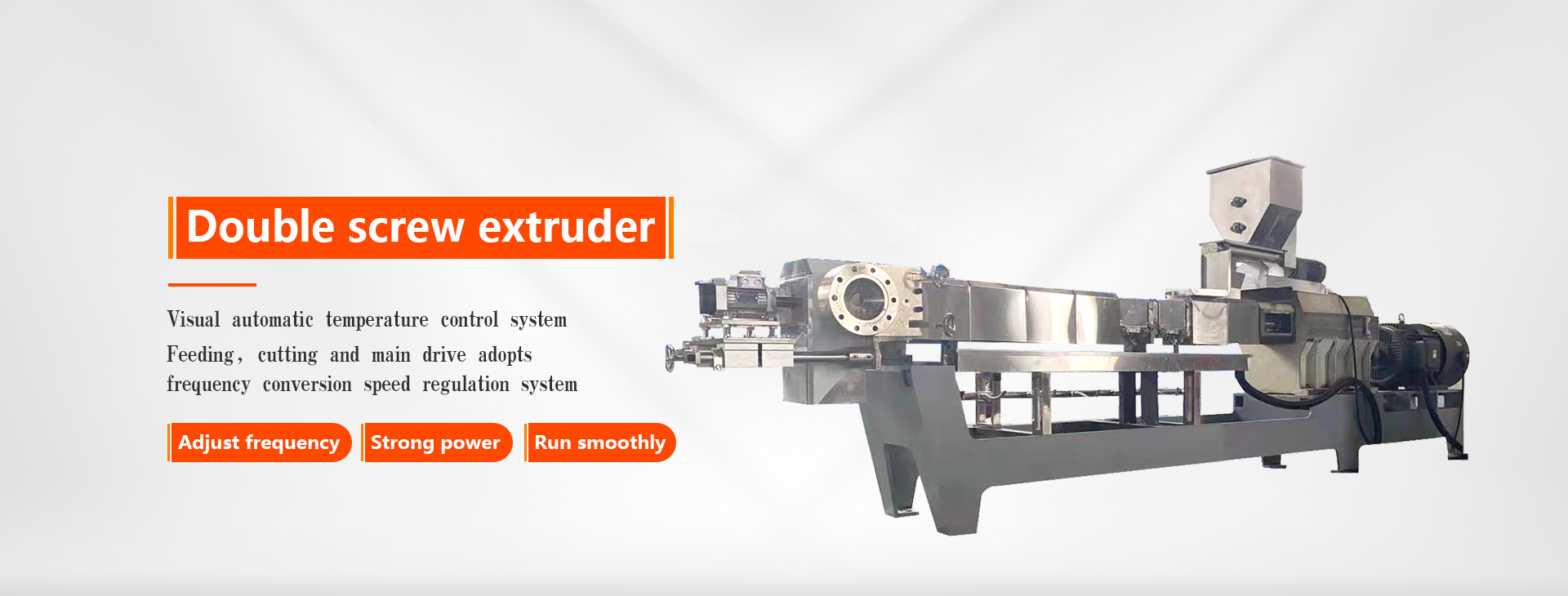

Fault analysis of power failure and overload of extruder

The extruder is an important process equipment in the press workshop. Due to its high temperature and high pressure operation, it has high requirements for the safe operation of workshop operators. If the equipment fails due to operation or external factors, such as power failure and overload of the extruder.

1) In case of power failure of the extruder itself, close the direct steam valve of the extruder. At the same time, open the indirect steam heating steam of the cylinder barrel of the extruder while withdrawing the die of the conical die head to keep the materials in the extruder and the chamber warm, so as to prevent the materials from sticking together after cooling and blocking the extruder, which makes it difficult to start up. Start the extruder after power supply. If the extruder cannot be started within half an hour, the turning gear shall be used to discharge the materials in the chamber.

2) In case of power failure in the workshop, open the bypass of the pneumatic valve for steam supply of the extruder in time, close the direct steam valve of the extruder, open the indirect steam valve of the cylinder of the extruder to insulate the materials in the extruder and the chamber, and handle them after the power is supplied.

The above two points are the treatment methods to solve the power failure and overload of the extruder.

It is committed to upgrading the overall technical level of microwave drying equipment, single extruder and extruder production line

With advanced technology, strict management and perfect service, the company has been highly praised by users at home and abroad, and has achieved very impressive performance, occupying a place in the expansion industry

-

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305 -

E-Mail:

E-Mail:

info@dongxuya.com -

Company ADD:

Company ADD:

No.14,DM Industrial Park,Jinan City,China

Scan