- Company News

- Industry News

- Question

Industry News

Causes and solutions of belt slipping in extruder

When the extruder is operating, the belt will slip. In fact, this is a very normal phenomenon.

1) The drive belt of the extruder is too loose, causing slipping;

2) The load of the extruder is too large (large feeding amount, small steam supply, poor discharge of the cone die, etc.)

Treatment method:

1) If the belt is loose, stop the extruder, lock the motor breakpoint and contact the machine maintenance to tighten the belt.

2) If the belt slips due to excessive load, if the belt slips seriously, it is necessary to exit the cone die head, turn down the steam valve, and reduce the feeding amount of the extruder. When the current of the extruder is reduced to the normal current, adjust the feeding amount and steam amount for mold production. Pay attention to the change of motor current of the extruder during mold production. After the mold is normal, slowly increase the feeding amount and steam amount until the extruder is in full load production. If the belt slips slightly, adjust the steam volume or feeding volume appropriately. Generally, adjust the steam volume.

The above is the reason for the belt slipping of the extruder and the solution.

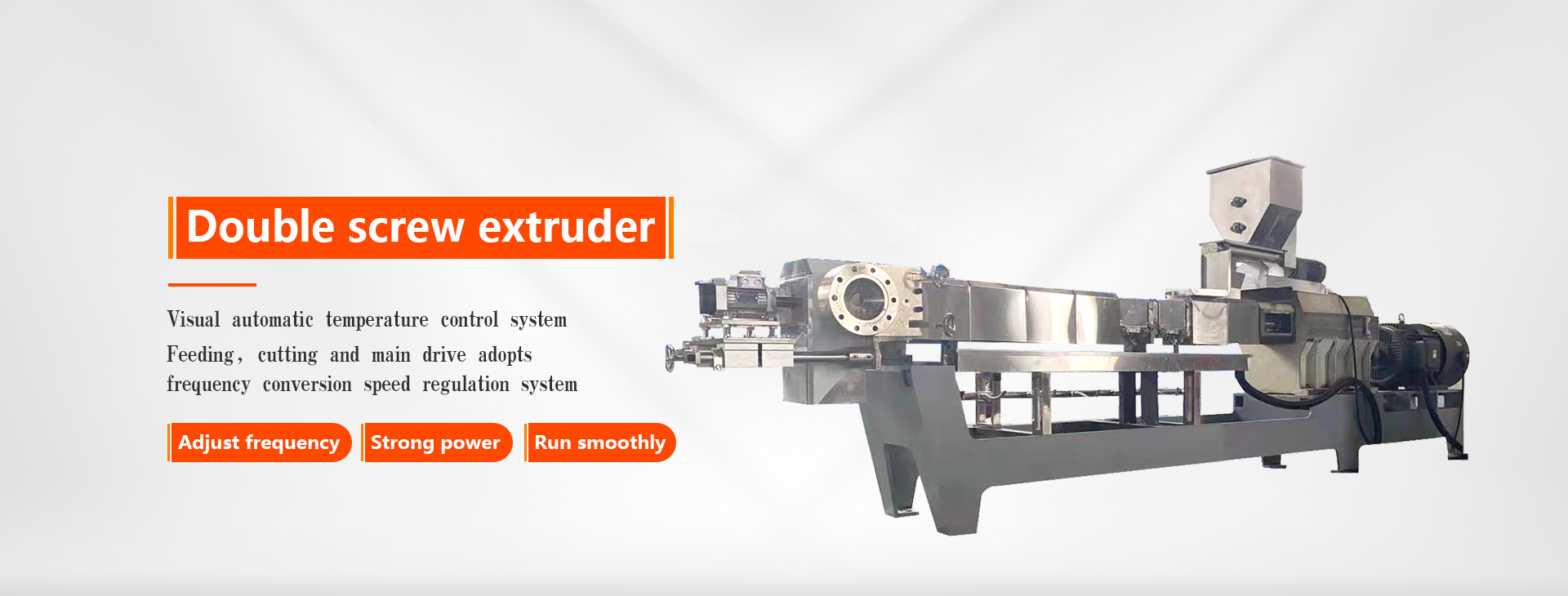

It is committed to upgrading the overall technical level of microwave drying equipment, single extruder and extruder production line

With advanced technology, strict management and perfect service, the company has been highly praised by users at home and abroad, and has achieved very impressive performance, occupying a place in the expansion industry

-

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305 -

E-Mail:

E-Mail:

info@dongxuya.com -

Company ADD:

Company ADD:

No.14,DM Industrial Park,Jinan City,China

Scan